Suspension & Chassis Design

Purpose

The purpose for this project was to create an independent front and rear suspension system for a vehicle. The goal with this process was to refresh my knowledge of suspension design and improve upon it. For this project the engine, drivetrain, and steering system were not taken into account, thus some aspects of the final chassis may appear incorrect.

Calculations and Code

While researching the required calculations to complete the design of an independent suspension system the decision was made to write code to make any future suspension calculations more efficient. To create this code I used the program Octave, which is similar to MATLAB. The code allows for parameters of the vehicle to be easily changed and produce new hardpoints for the suspension arms. The required parameters are the desired track, wheelbase, wheel package, center of gravity, desired kingpin angle, wheel travel, caster angle, and anti-dive. With these parameters the code will go through the steps of independent suspension design and produce front view and side view plots with hardpoints.

Plotting Suspension Geometry

Front View

The front view shows the wheel and vehicle body as rectangles and the origin is at the center of the tire contact patch. The wheel and vehicle centerlines are graphed with dotted lines to show the reference points required for the calculations. The scrub radius is then calculated and plotted as the vertical dashed line inside the wheel. The scrub radius for this vehicle is calculated as 35% of the tire width, this is because the design for this suspension is from scratch. Now having the scrub radius, the kingpin axis can be plotted at the desired angle. The upper and lower ball joints will be located on this axis. For this project, the ball joints are kept inside the inner rim parameter and are located at ¾ of the inner rim radius then projected onto the kingpin axis. The instant center from the front view is now calculated so that the control arms can be plotted. The front view swing arm (FVSA) is needed to locate the instant center. The FVSA length was found by calculating the camber change rate (CCR) which is the kingpin inclination angle divided by the wheel travel. The FVSA length is then 1 divided by the tangent of CCR. The instant center is now located by drawing a line through the center of the contact patch through the roll center until it intersects a vertical line located at the horizontal distance of the FVSA length. The control arm axes can then be found by drawing a line from the respective ball joint to the instant center. The locations where these lines intersect the body are the control arm mounting locations.

Side View

The side view shows that the profile of the wheel and the origin is placed at the center of the contact patch. The wheel centerline is plotted with a dotted line to provide reference for the caster. The caster angle is plotted as a dashed line at an angle that passes through the wheel center. The ball joints from the front view are then projected onto the side view. The final location of the ball joints is where they intersect the caster line. To find the control arm hardpoint locations, the instant center of the side view must be found. The IC is found by assuming a percentage of anti-dive for the vehicle. A side view swing arm (SVSA) length is estimated here as ¾ the distance to the center of gravity and the anti-dive height is then calculated. Then, a line is drawn from the center of the contact patch to the anti-dive height and where this intersects a vertical line at a horizontal distance of SVSA length is the instant center location. The control arm points are then projected from the front view to the side view and moved in the X direction a desired length, these are now the front control arm hardpoints. The control arm pivot axes can then be found by drawing a line from the front control arm points to the instant center. The rear control arm hardpoints must be located on these axes at a desired X distance. Now, the ball joints and control arm mounting locations are in 3D coordinates from a combination of the front and side views so they can be displayed in a 3D plot before moving to CAD.

3D Hardpoints

The code will then generate a 3D plot of the hardpoints and connect them appropriately to display the control arms. This provides the suspension arms to be inspected for confirmation of design before the time is taken to enter the hardpoints into CAD and begin modeling. Once the suspension arms were reviewed, the modeling of the suspension system began. The CAD program used for this project was Autodesk Fusion 360.

Front Suspension

Control Arms

The front suspension was modeled using an addon script for Fusion 360. This addon allows for individual points to be placed in the 3D workspace by entering coordinates. The control arms are a simple design and only serve to confirm the motion of the suspension not to support vehicle forces. The process used for design in Fusion 360 was to sketch lines in 3D following the hardpoints, then to use the pipe tool to create a simple tubular look. This process was repeated for the remaining control arm and the knuckle.

Steering

The steering system in this chassis is simple and for the purpose of suspension simulation. The required calculations for rack positioning to have appropriate Ackerman steering was not performed, neither were the calculations for the tie rod locations to reduce toe with suspension travel. For the scope of this project, the tie rod was located midway between the front upper and lower control arm hardpoints.

Spring and Damper

Rear Suspension

Control Arms

The rear suspension is nearly identical to the front, this is due to the estimated center of gravity for this vehicle being in the center of the wheelbase. This is important to note because the side view swing arm (SVSA) will change depending on the center of gravity location. This SVSA change will alter the geometry of the suspension and a second iteration of the initial code will have to be ran and adjusted for the rear. This is a future goal of this project, to make additional chasses with different center of gravity locations. The rear suspension is a mirrored version of the front suspension, however an additional link is needed to control the toe of the rear wheels. The link that is added is the Toe Arm.

Toe Arm

The body hardpoint for the Toe Arm was calculated using the same method as the control arms. This is done by connecting the hardpoint to the sideview instant center to achieve the same center of rotation. The pivot point for the Toe Arm is placed along the axis formed by this line and the Toe Arm link is then extended and connected to the rear knuckle.

Spring and Damper

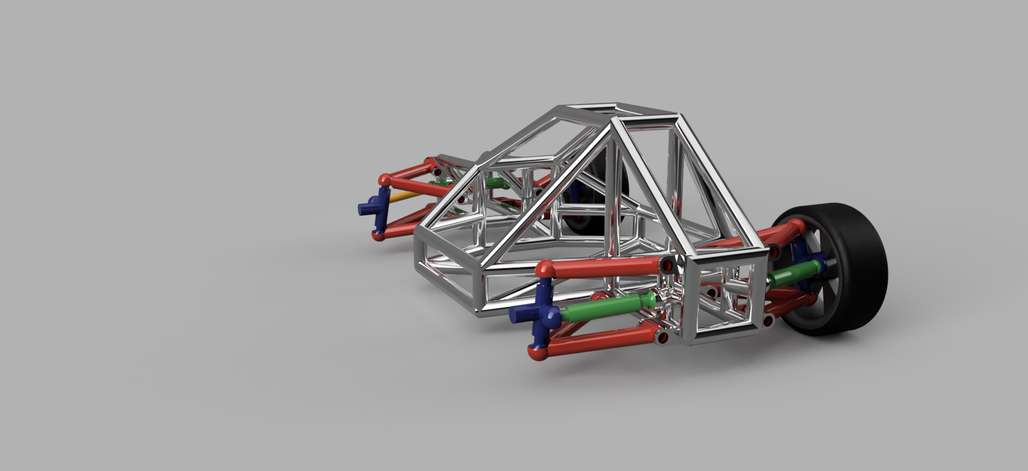

Frame Design

The frame was modeled after a formula car with a tubular construction. The first step was to create the mounting locations for the control arms. These mounting locations were created by extruding a frame rail parallel to the control arm axis. This allows for the pin joints to operate without binding throughout suspension travel. Once all of the control arms had frame rails, connections of the frame rails to one another was completed with simple box like construction. These box like frame sections are now the front and rear sub frames. The center portion of the frame was created by starting from the front sub frame and outlining a shape that followed a formula car and finishing at the rear sub frame. The front portion has a taper to allow for wheel clearance with turning. The sketched portion of the frame was then built up slightly and a second run of tubing was ran to create a visual of side impact safety. The remaining portion of the frame was a roll cage where the outer most points of the frame were brought up and tapered to a plane above the cockpit.